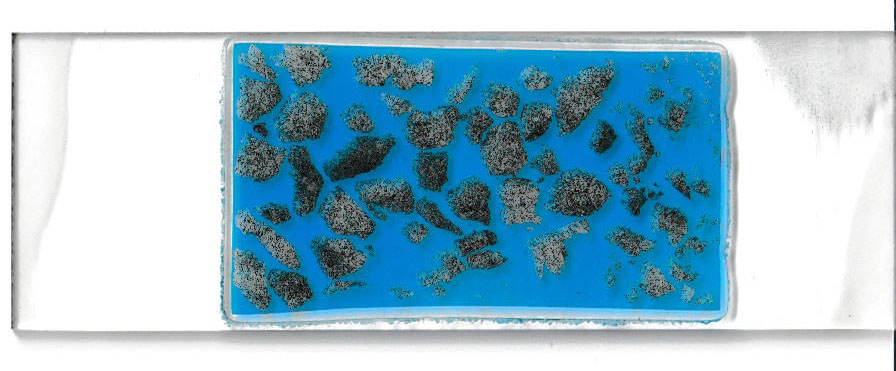

Standard Thin Section Preparation includes trimming of samples to appropriate size and impregnation with your choice of the following epoxy resins.

- Clear

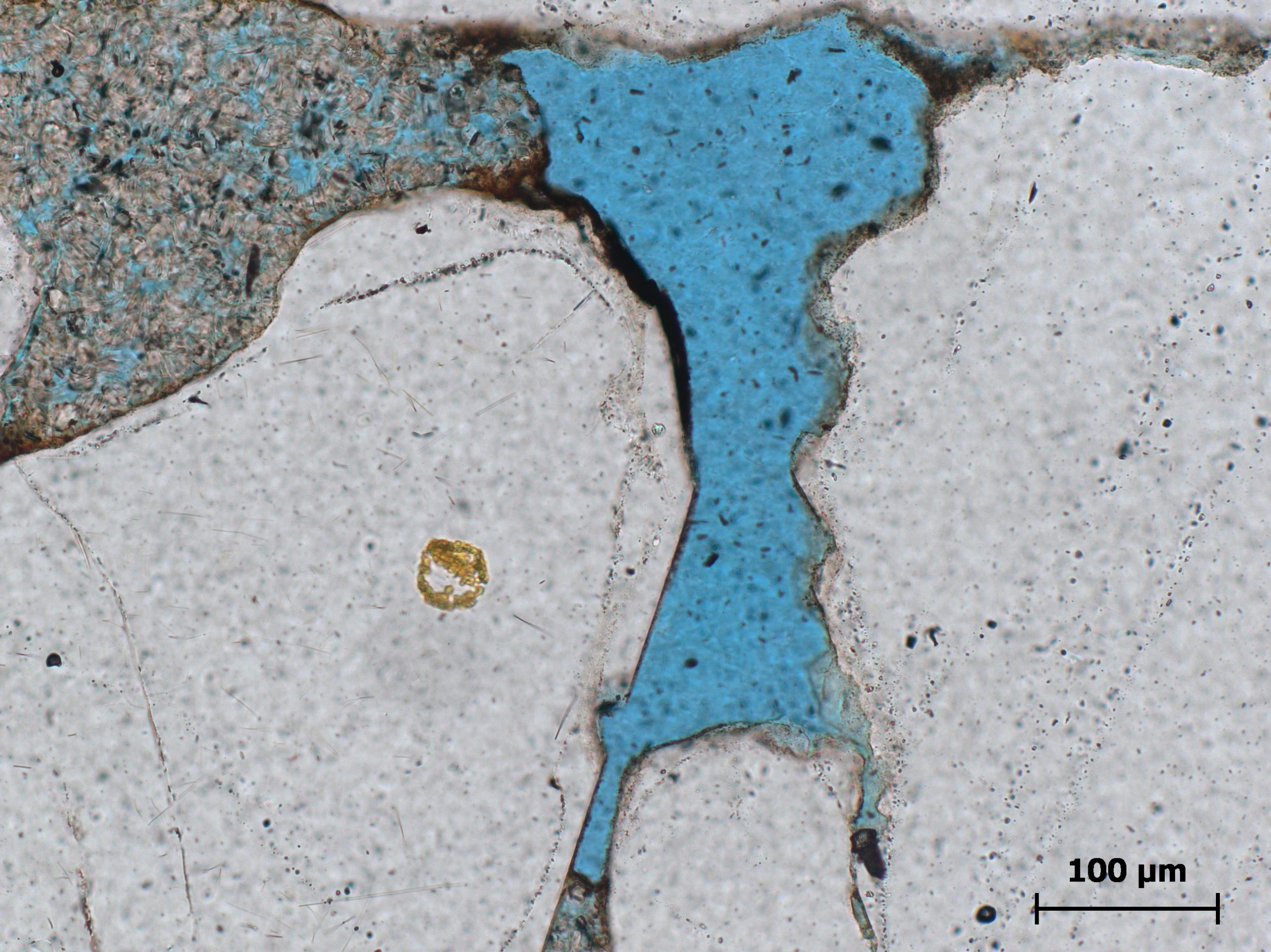

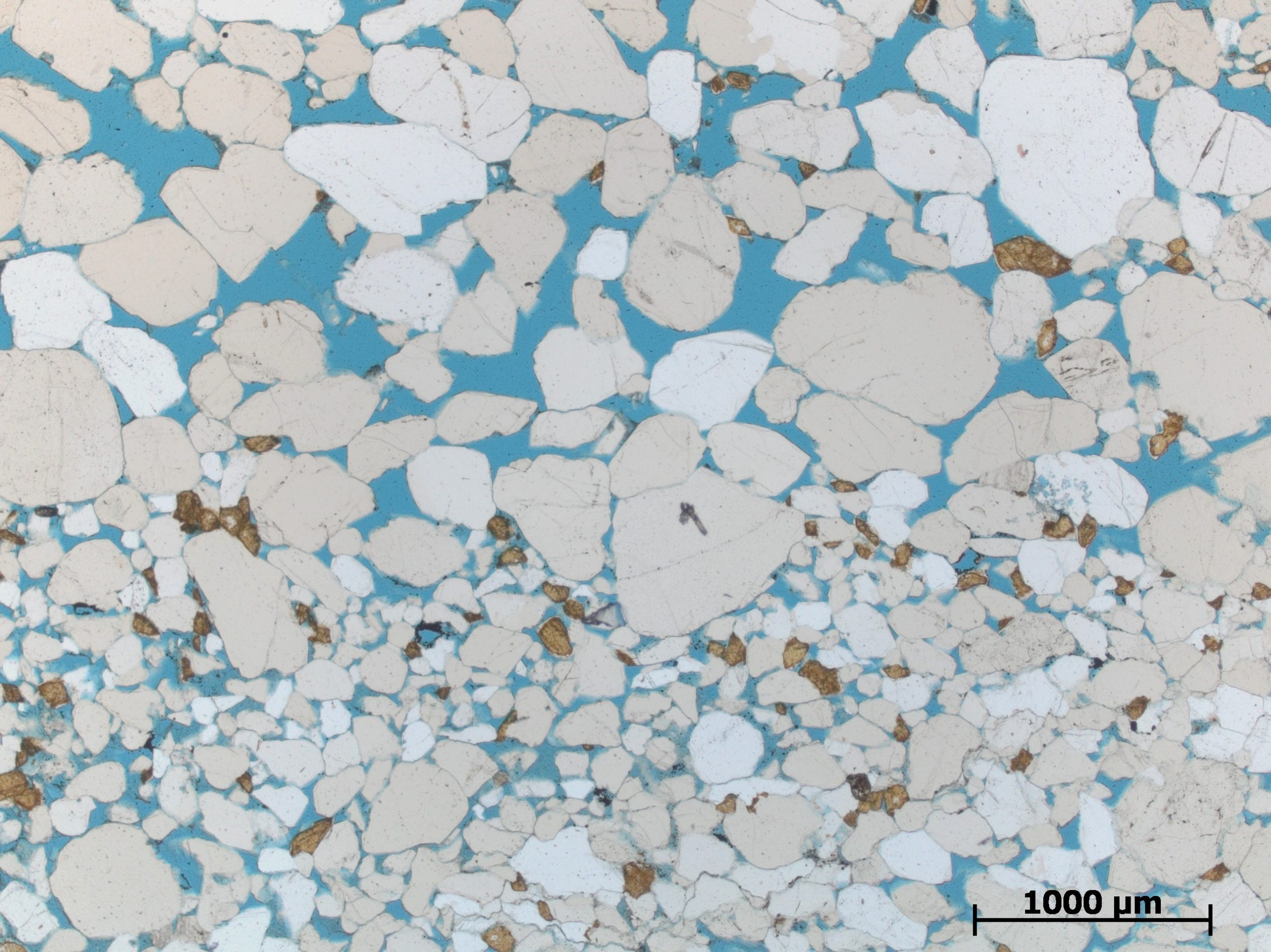

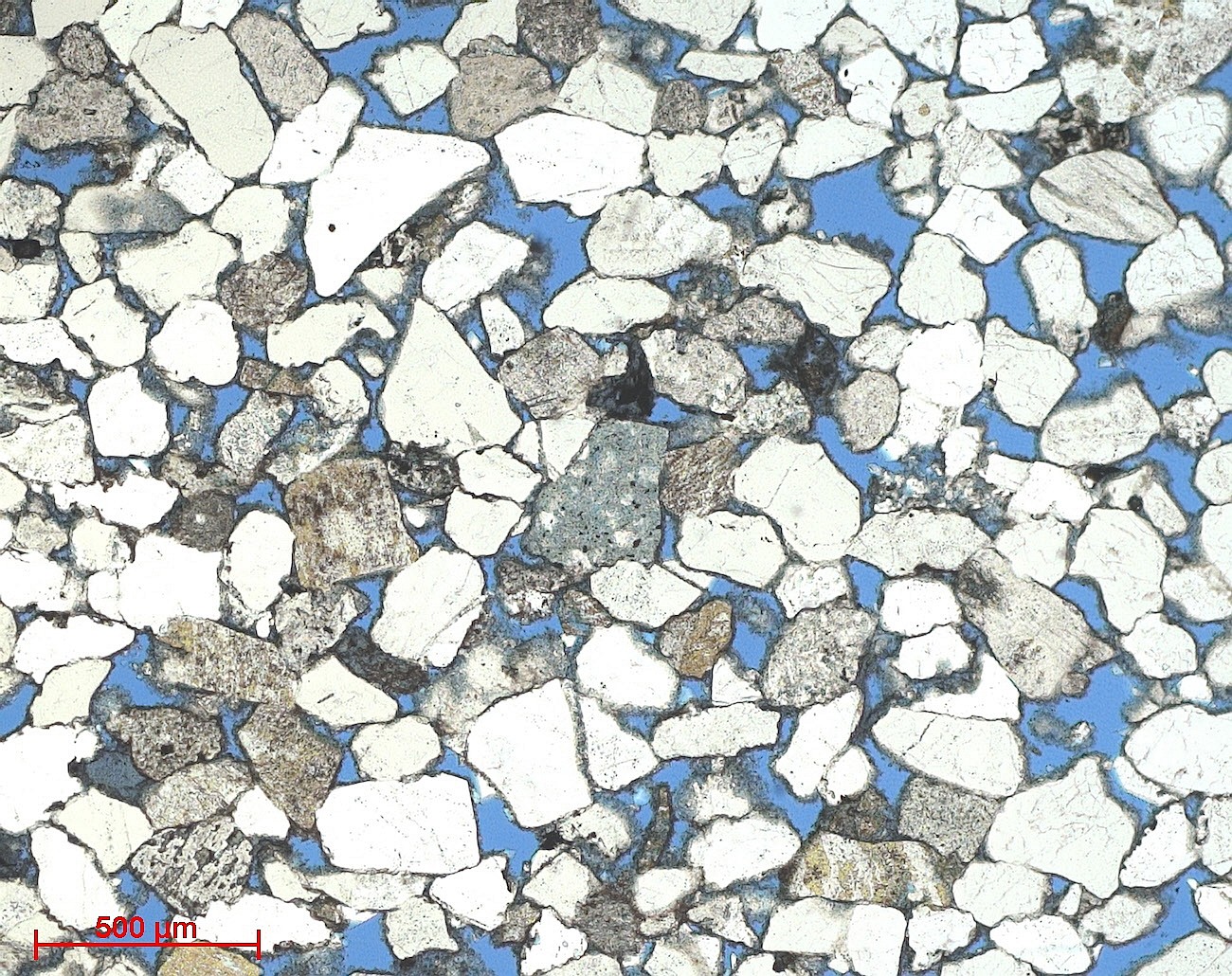

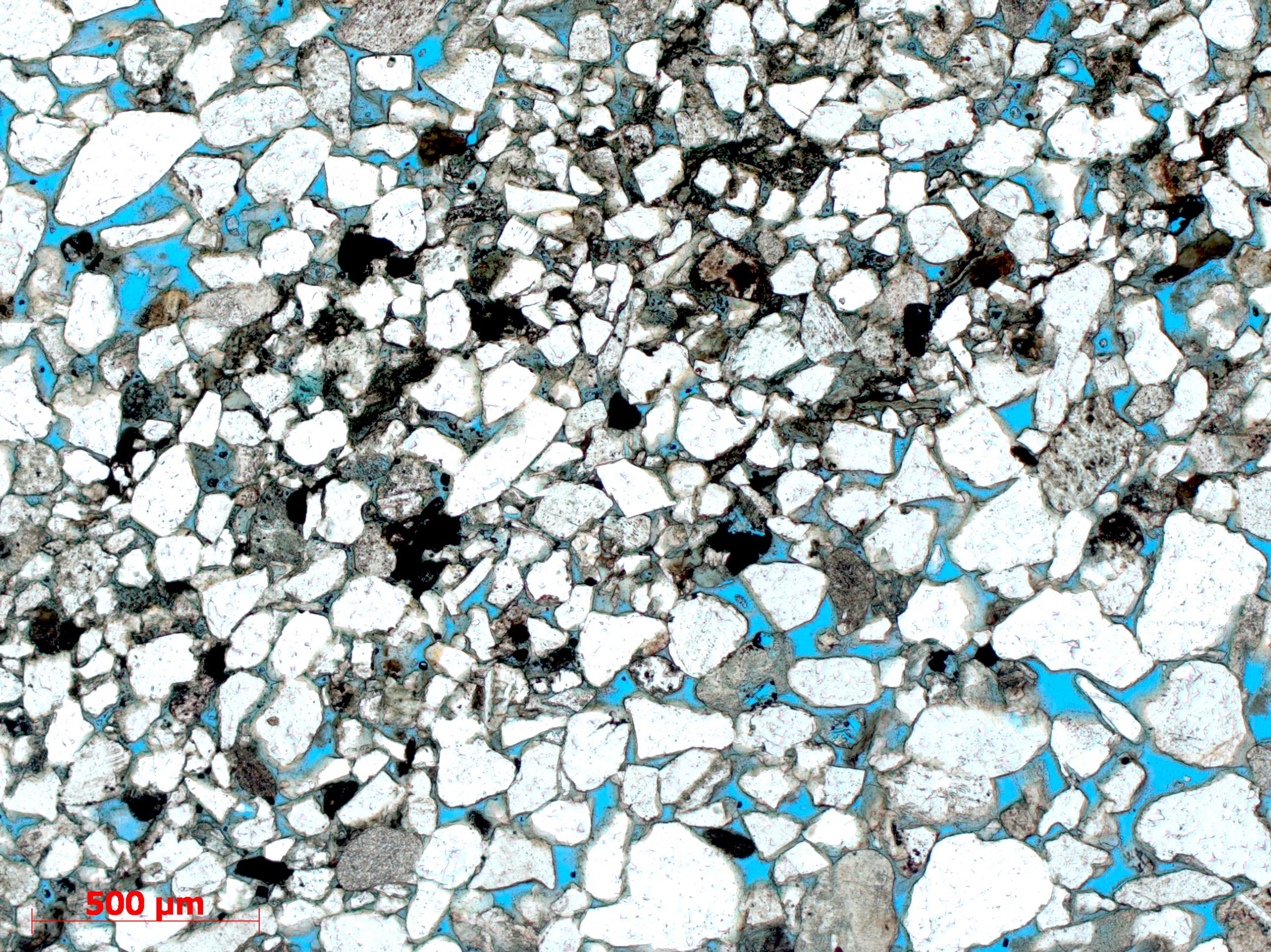

- Blue, to highlight porosity

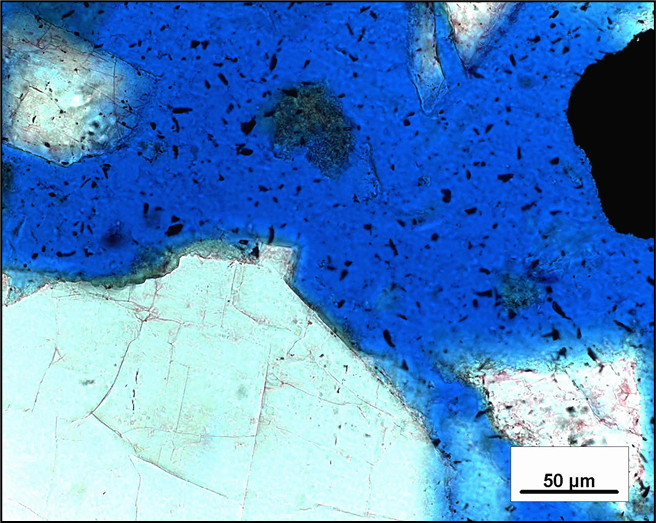

- Blue with epifluorescent spike, to highlight microporosity

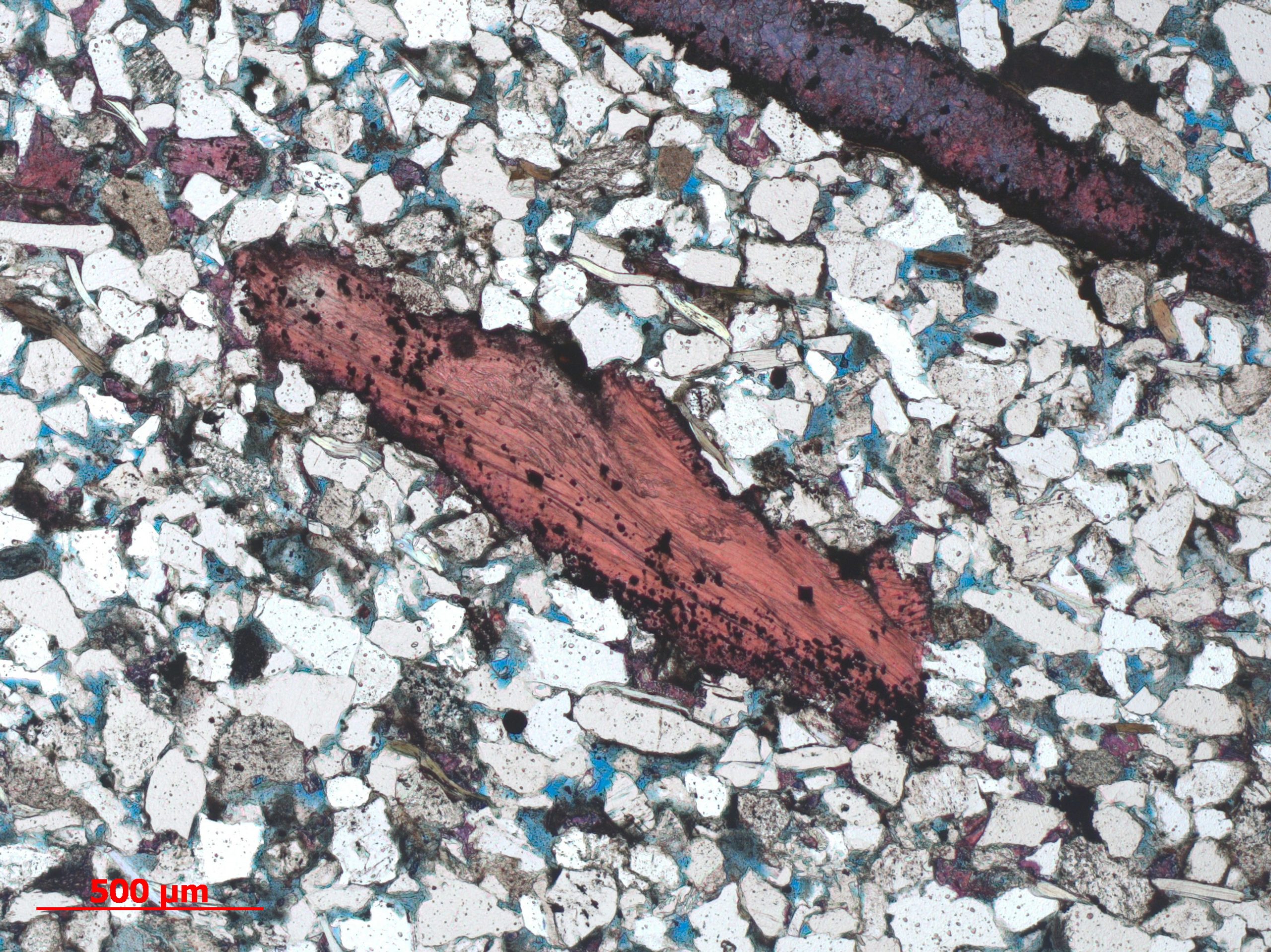

- Rhodamine B, also to highlight microporosity and generally utilized in mudrocks

Our impregnation process is comprised of three vacuum stages, to initially fill pores with resin, followed by a high pressure stage (1200psi). Samples are allowed to cure under pressure to eliminate to presence of bubbles in the resin. In addition, our resin is mixed and then filtered to remove any undissolved dye particles, prior to application. Final grinding of the sections is carried out in a manner that does not embed abrasive particles in the epoxy (grit) or create excessive damage to quartz grains (induced cracking).

Slide sizes offered are 1”X2”, 1”X3”, and 2”X3”